SCANNING & INSPECTION

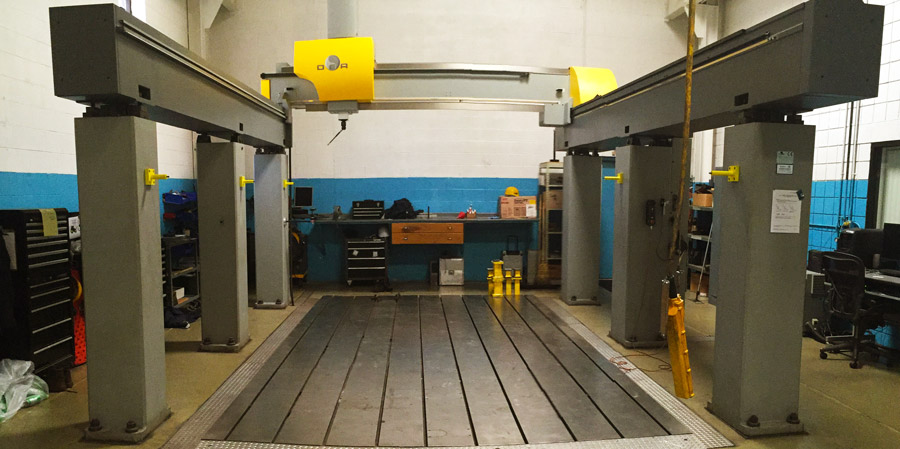

CMM Inspection

With the panel setup in a checking fixture, in carline position, the CMM will check for proper locations of holes, trim edges, as well as form and flange locations, and the general shape of the panel using many check points on panels that came from the operations. With this information gathered, this will then be compared with the computer generated final product of said panel, to a predetermined set of tolerances depicted by the parent company.

Scanning Inspection

We have the ability to perform in-house 3D scanning of panels on a fixture, or a panel in free state of any operation. This information can then be converted to data that can be read into software that overlays either data to final product data, in full color spectrum, to show deviations from as is, to should be. This knowledge allows for less turn-around time to make adjustments in the operations, if required.

Scanning capabilities also include scanning full lower or upper die sets at a time.

Revising dies that require reverse engineering surface/shape change, trim or pierce changes, or product changes.

Utilizing both the Scanning and CMM, then compared to the computer generated product data, the information can then be gathered to make the necessary adjustments in surface, trim, and pierce moves required to make the panel check within given tolerances. In the case of product changes, it will be determined which operation is best suited to add the change.

With the advent of CMM, 3D Scanning, and the ability to overlay in full color spectrum, our quality control measures have the ability to meet the product specifications, in a timely manner. This is one of many reasons DieTech North America has excelled in customer satisfaction.

DieTech North America has been fortunate to work with General Motors, Ford Motor Company, and Fiat Chrysler.